| Sign In | Join Free | My hardware-wholesale.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My hardware-wholesale.com |

|

Place of Origin : Jiangxi, China

Brand Name : BLU-RAY

Certification : CE, ISO, CMC

Supply Ability : 100 Set/Sets per Month

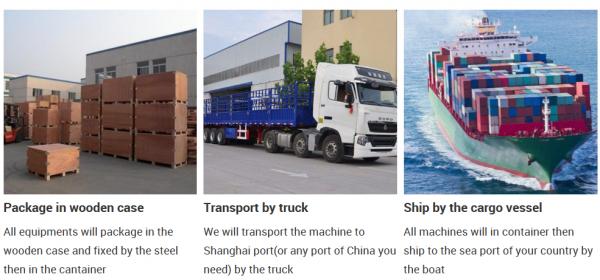

Packaging Details : The filling machine will installation and testing welled then whole set packed in one big wooden case then in container, so you need installation again, only you need to do is connect your wire to our control box.

MOQ : 1 Set/Sets

Price : $5,000.00 - $10,000.00 / Set

Type : Filling Machine

Condition : New

Application : each type of powder materials

Packaging Type : Bags, packing 20-50kg materials into open mouth bags

Packaging Material : Wood, whole set equipment in one wooden case then in container

Automatic Grade : Semi-automatic

Driven Type : Electric and Pneumatic

Voltage : 220V/380V/50HZ or as your need

Power : 3-6kw

Dimension(L*W*H) : depends

Weight : 1000kg

Product name : powder filling machine

Three load cell : 3 load cell high weighing accuracy

Three travelling cylinder : feeding speed with fast-midium-slow

Control box : full touch screen panel

Automatic bag clamp : sensor control

PLC system : easy operating

Packing material : any type of powder

Sewing machine : full automatic with data record

OEM service : 15 years R&D experience

Quality warranty : one year

After-sales Service Provided : Engineers available to service machinery overseas

Port : Shanghai or any port of China

25kg animal feed additive filling machine, auger powder filling machine

| Product Name | Dual screw/auger feeder packing machine | ||

| Item | DCS-50WF | DCS-50F | DCS-50SF |

| Application Materials | Powder materials such as flour, starches, lime powder, cement, fertilizer,silica sand powder,nitrate of potash, ammonium sulfate etc | ||

| Display Resolution | 5g, 10g | ||

| Weighing Range | 20-50kg/bag or customized needs | ||

| Precision | +/-(0.1-0.2)% FS depends on your materials characteristic | ||

| Packing Capacity

| 120-180bags/hour | 240-360bags/hour | 400-500bags/hour |

| the packing speed most depends on your materials characteristics and your worker placing bag efficiency, if your worker placing the bag more quickly to the packing machine outlet, the packing machine speed can be more fast. | |||

| Dimension(L*W*Hmm)

| 300*125*260cm | 300*125*330cm | 400*120*370cm |

| the size can be customized you need as per your actual | |||

| Power Supply | AC220V/380V, 50HZ, 1P/3P | ||

| Air Source | 0.5-0.7 Mpa | ||

| Power | 3KW-6KW | ||

| Working Temperature | -10~40 ℃ | ||

| Relative Humidity | ≤90% RH(Non-condensing) | ||

| Description | Remarks |

| Packing scale framework | Floor structure, high quality carbon steel |

| Feeding mechanism | Screw feeding type, three grade feeding speed with fast-medium-slow |

| Weighing sensor | Installation 3pcs(DCS-50WF,DCS-50F)/6pcs(DCS-50SF) load cell, famous brand |

| Control system | PLC system, full automatic, data record & print function |

| Control box | Color touch screen, English/Chinese interface |

| Cylinder | AirTAC brand, big force, high quality, more stable, long service life |

| Solenoid valve | AirTAC brand, with indicator |

| Electric component | Schneider brand, short circuit protection function |

| Pneumatic component | AirTAC brand, stable and reliable |

| Motor | Frequency conversion motor with smooth working |

| Automatic sewing machine | Photoelectric induction control, automatic thread knife cut, date record & print |

| Belt type bag conveyor | Speed governing design |

DUAL AUGER FEEDING powder packing/packaging/bagging/filling machine picture

The filling machine working process is manual placing the bag to the packing machine outlet-automatic bag clamp-automatic materials feeding-automatic weighing-automatic discharge the materials into the bags-bag automatic release-well discharged bags conveying to the closing machine by conveyor-bag closed by sewing(double thread stitching) or heat sealing.

Raw materials-cutting-drilling-welding-folding-polishing-rust prevention-paint spraying- assembling-

testing-packaging and transport-after service

|

|

ISO Approved Dual Screw 25kg Animal Feed Packing Machine Images |